We offer one-stop services from mold design and development to mold manufacturing and injection molding.

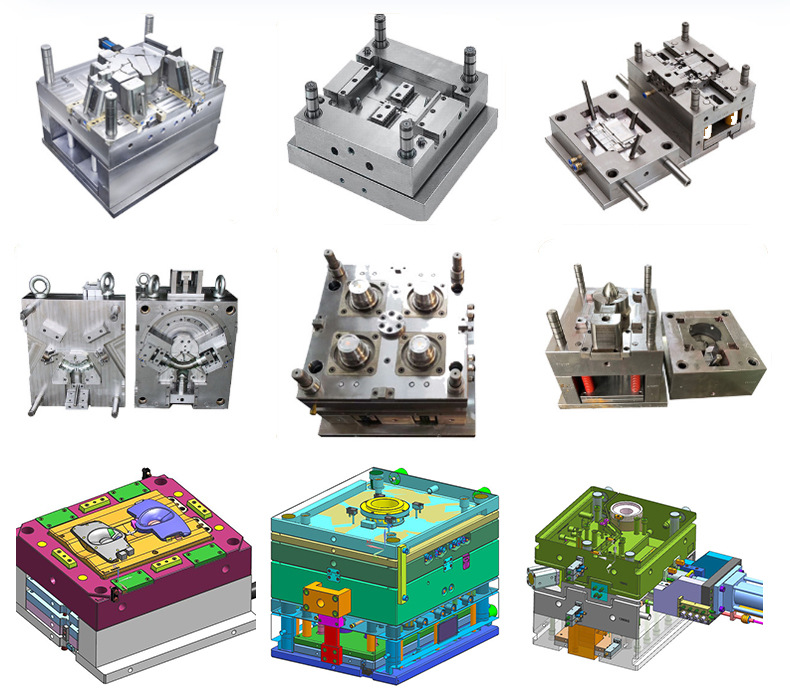

High quality tooling is the foundation of a perfect product. ZSD can provide a full range of services in injection molding and die-cast molds, in cast P20, 738,718, NAK80, H13, S136 or 420SS mold insert steel from Germany and Japan, creating precision products to meet your tooling requirements. Our professional team will advise and assist you in advance to complete production, along with any design changes, ensuring the minimum time from development to market entry, from every aspect of the design, manufacturing, and right up to final assembly. Check out a few examples in our gallery.

Our advantages include:

1,Expertise and Experience: We are staffed with skilled professionals who have extensive experience in designing and manufacturing molds. We possess the know-how to create molds that meet specific requirements, ensuring the best possible results for our clients.

2,Customization: We specialize in producing custom molds tailored to the unique needs of each client. This level of customization allows businesses to have molds that precisely match our product designs and specifications.

3,Precision and Consistency: We utilize advanced technologies and precision machinery to create molds with tight tolerances and consistent results. This ensures uniformity in the manufactured products, reducing defects and waste.

4,Faster Production: By outsourcing mold production to a specialized factory, businesses can save time and resources. We have streamlined processes that enable quicker turnaround times compared to in-house mold making.

5,Cost-Effectiveness: While there may be initial costs associated with mold development, working with us can be cost-effective in the long run. It reduces the need for significant upfront investments in mold-making equipment and skilled labor.

6,Innovative Solutions: We stay updated with the latest advancements in mold-making technologies and materials. We can offer innovative solutions to clients, ensuring our products remain competitive in the market.

7,Quality Assurance: ZSD maintain strict quality control measures throughout the manufacturing process. We conduct thorough inspections and tests to ensure the molds meet the highest quality standards.

8,Material Selection: ZSD can guide clients in choosing the most suitable materials for our molds, taking into consideration factors like durability, product requirements, and cost-effectiveness.

9,Long-Term Partnerships: Establishing a relationship with a reliable ZSD can lead to long-term partnerships. As we becomes familiar with the client’s needs, they can provide ongoing support and continuous improvement for future projects.

10,Focus on Core Competencies: Outsourcing mold production to ZSD allows businesses to focus on your core competencies and main areas of expertise, ultimately leading to greater efficiency and productivity.

In summary, We offer expertise, customization, precision, and cost-effectiveness, allowing businesses to access high-quality molds tailored to your requirements. Working with a reputable We can significantly enhance the efficiency and success of the manufacturing process.

Visit our Engineering page to find out more about our equipment, certifications and how we work.