We offer one-stop services from mold design and development to mold manufacturing and injection molding.

Rapid Prototyping will get your ideas off the drawing board and into testing effectively and efficiently, via CAD, 3D printing, CNC machining, and more. We understand that time is money, and that quality and accuracy are paramount. Our methods are ideal for producing designs with precision and speed. ZSD will discuss your needs in detail to bring your plan to life in the form of a scale model. Taking care to get this stage right is a great step along the way towards tooling and production, to take your concept from idea to reality.

Rapid prototyping is a product development approach that involves quickly creating a scaled-down version or model of a product or system to test and validate its design before full-scale production. The main goal of rapid prototyping is to accelerate the product development process , reduce the time and cost required for traditional manufacturing.

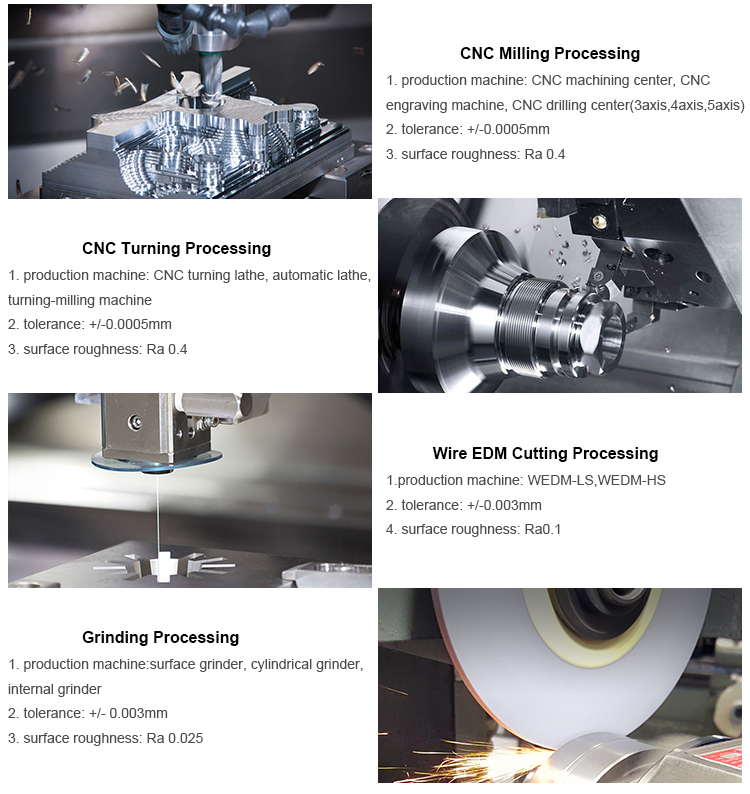

The process typically involves using computer-aided design (CAD) software and various rapid prototyping technologies, such as 3D printing, CNC machining, or laser cutting, to fabricate physical prototypes. These prototypes allow designers, engineers, and stakeholders to visualize and evaluate the product’s form, function, and performance.

Advantages of Rapid Prototyping:

Faster development: Rapid prototyping enables quick iterations and modifications,reducing the overall development time and allowing products to reach the market more swiftly.

Cost-effective: Identifying design flaws and functional issues early in the process helps avoid expensive modifications during later stages of production.

Improved communication: Physical prototypes offer a tangible representation of the product, making it easier to communicate design ideas and gather feedback from stakeholders.

Better design validation: Prototyping allows designers and engineers to assess the product’s suitability for its intended purpose and identify potential improvements before final production.

Flexibility and customization: Rapid prototyping technologies can accommodate a wide range of materials and designs, making it easier to create custom products and components.

Reduces risk: By testing prototypes, potential issues can be identified and resolved early, reducing the risk of costly errors in the final product.